The Wandaye mineral processing team has been involved in the field of mineral processing and engineering transformation of non-metallic minerals both at home and abroad since 2014, mainly for kaolin, potassium sodium feldspar, quartz and so on. Relying on professional mineral processing technology and long-term practical experience, Wandaye conducts in-depth investigation and Research on customer projects. From mineral processing experiment, mineral analysis, process design, equipment matching, installation and commissioning, after service and so on, To customize the best whole line engineering technology solutions for customers.

Wandaye Mineral Processing Engineer Team Visits Mine Site

Wandaye Mineral Processing Engineer Team Visits Mine Site Wandaye Mineral Processing Engineer Team Goes To Customer Factory For Survey And Design

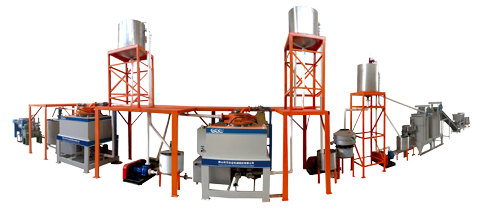

Wandaye Mineral Processing Engineer Team Goes To Customer Factory For Survey And Design Wandaye Completes Operation Of Its Ore Dressing Line Project Designed For Customers

Wandaye Completes Operation Of Its Ore Dressing Line Project Designed For CustomersWandaye has an experienced team of specialized mineral processing engineers, providing the mineral processing test of kaolin, potassium sodium feldspar, quartz and other non-metallic minerals, mineral analysis, process design, and the best solution for the whole line project.

So far, the company's ore dressing test mainly consists of two parts: beneficiation laboratory and semi-industrialization test line.

Your satisfaction is our pursuit. Wandaye insists customer efficiency and tailor the best investment plan to every customer.

Raw material preparation

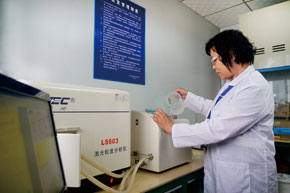

Raw material preparation The technician conducts the ore sample assay

The technician conducts the ore sample assay Laboratory Raw Material Storage Area

Laboratory Raw Material Storage Area The content of sample element was detected by using silicate analyzer

The content of sample element was detected by using silicate analyzer The particle size distribution was detected by laser particle size analyzer

The particle size distribution was detected by laser particle size analyzerThe process design mainly includes three parts: feasibility study, preliminary design, and construction drawing. The most important point of process design is that all of its work must be based on detailed field investigations. Therefore, Wandaye Machinery will first conduct a comprehensive field visit to the customer's mine, including the selection of mine ore, site, hydropower, transportation, geography, etc.

Through professional data collection and feasibility study, a feasible design scheme is finally determined for the whole line project. Through the feasibility study design scheme, customers can understand the key issues such as the overall scale, investment scale, expected revenue and so on.

The quality of the drawing is high, and the whole design is simulated by CAD and 3D. The construction period is guaranteed.

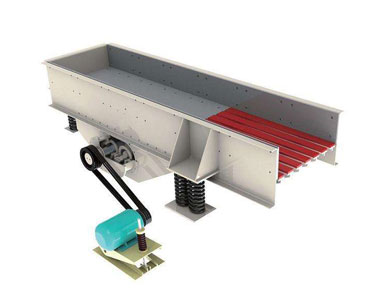

In the whole line engineering production line of washing kaolin production line equipment, potassium sodium feldspar production line equipment, water grinding quartz sand production line equipment, etc., the main equipments used are: Program Controlled Automatic Oil-cooling Electromagnetic Slurry Separator Series, Vertical Ring High Gradient Magnetic Separator Series, Permanent Magnet Wet Magnetic Iron Removal Machine Series etc. Other equipment products such as crusher, ball mill, dewatering screen, feeder, sand washer, filter press, etc., we have strategic partners, can be purchased on behalf of the whole line one-stop service. (Pictures are for reference only)

Program Controlled Automatic Oil-cooling Electromagnetic Slurry Separator Series

Program Controlled Automatic Oil-cooling Electromagnetic Slurry Separator Series Vertical Ring High Gradient Magnetic Separator Series

Vertical Ring High Gradient Magnetic Separator Series Permanent Magnet Wet Magnetic Iron Removal Machine Series

Permanent Magnet Wet Magnetic Iron Removal Machine Series Jaw Crusher

Jaw Crusher Wet overflow ball mill

Wet overflow ball mill Dewatering screen

Dewatering screen Spiral sand washing machine

Spiral sand washing machine Feeder

Feeder Plate and frame filter press

Plate and frame filter pressThe Wandaye mineral processing team has been involved in the field of mineral processing and engineering transformation of non-metallic minerals both at home and abroad since 2014, mainly for kaolin, potassium sodium feldspar, quartz and so on.

Solution of Kaolin Whole Line Project

Kaolin is a non-metallic mineral, a clay and clay rock dominated by kaolinite clay minerals. Kaolin is widely used in paper, ceramic and refractory materials, secondly in coatings, rubber fillers, enamel glazes and white cement materials, and in small quantities in plastics, paints, pigments, grinding wheels, pencils, household cosmetics, soaps, Pesticide, medicine, textile, petroleum, chemical, building materials, national defense, etc.

Solution of Kaolin Whole Line Project

Kaolin is a non-metallic mineral, a clay and clay rock dominated by kaolinite clay minerals. Kaolin is widely used in paper, ceramic and refractory materials, secondly in coatings, rubber fillers, enamel glazes and white cement materials, and in small quantities in plastics, paints, pigments, grinding wheels, pencils, household cosmetics, soaps, Pesticide, medicine, textile, petroleum, chemical, building materials, national defense, etc.

Potassium-sodium feldspar whole line engineering solutionPotassium feldspar is usually flesh red, yellow and white, with low melting point, long melting interval and high melting viscosity. It is widely used in ceramic billets, ceramic glazes, glass, electric ceramics, abrasive materials, etc. Albite is generally a glass crystal, which is the raw material for making glass and ceramics. Albite is mainly used in making ceramics, soap, ceramic tile, floor tile, glass, abrasive Abrasives and so on. It is mainly used in glaze on ceramics.

Potassium-sodium feldspar whole line engineering solutionPotassium feldspar is usually flesh red, yellow and white, with low melting point, long melting interval and high melting viscosity. It is widely used in ceramic billets, ceramic glazes, glass, electric ceramics, abrasive materials, etc. Albite is generally a glass crystal, which is the raw material for making glass and ceramics. Albite is mainly used in making ceramics, soap, ceramic tile, floor tile, glass, abrasive Abrasives and so on. It is mainly used in glaze on ceramics. Quartz sand line engineering solutionQuartz sand is a quartz particle obtained by crushing quartz stone. Quartz stone is a non-metallic mineral, a hard, wear-resistant, chemically stable silicate mineral. Quartz sand is an important industrial mineral raw material, non-chemical dangerous goods, widely used in glass, casting, ceramic and fireproof materials, smelting ferrosilicon, metallurgical flux, metallurgy, construction, chemicals, plastics, rubber, abrasives, filter materials and other industries.

Quartz sand line engineering solutionQuartz sand is a quartz particle obtained by crushing quartz stone. Quartz stone is a non-metallic mineral, a hard, wear-resistant, chemically stable silicate mineral. Quartz sand is an important industrial mineral raw material, non-chemical dangerous goods, widely used in glass, casting, ceramic and fireproof materials, smelting ferrosilicon, metallurgical flux, metallurgy, construction, chemicals, plastics, rubber, abrasives, filter materials and other industries.