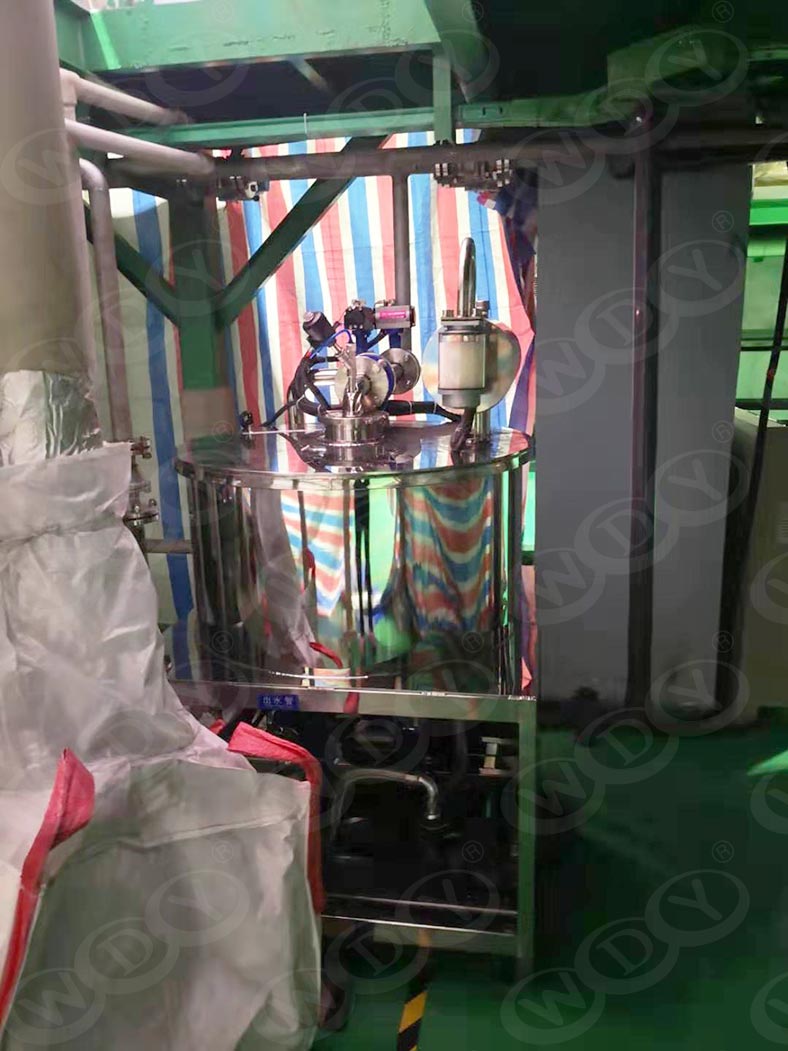

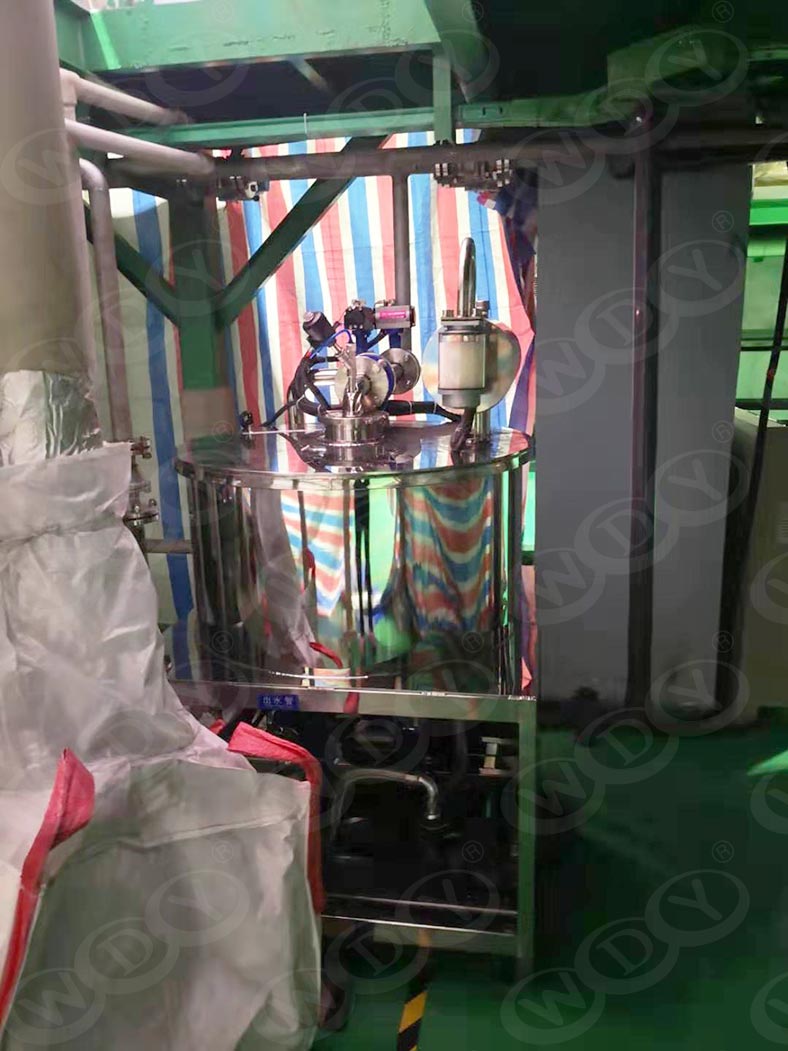

This is a case of removing magnetic impurities contained in

battery materials in Xiamen City, Fujian Province. The case used are

New Type Electromagnetic Slurry Magnetic Separator Series by WDY.

The new type electromagnetic slurry

magnetic separator adopts stainless steel shell, which is beautiful and easy to clean. The magnetic field distribution is uniform, magnetic field gradient is high, and energy consumption is low. Inside it adopts oxide film coil, which has the excellent performance of temperature resistance, oxidation resistance, conductivity and field strength etc. Usually the battery slurry has a weak acid or alkalinity, the cavity is made of food-grade 316L stainless steel tube, and it can effectively resist corrosion; This machine adopts water and oil double cooling system, make the temperature drop 20℃, extend coil life, the machine performance is more stable. The upper part of the magnetic cavity is designed with convenient dismantle interface, which is convenient for production and dismantle. The medium mesh is made of special materials, easy to clean and not easy to rust. The valve adopts imported materials to avoid the influence because of copper, iron and zinc on the original slurry. Automatic operation, no extra manual operation. Compared with previous models, the output is more powerful and the magnetic field intensity is doubled,

which is suitable for medium and large production lines in the battery slurry industry.

The new type electromagnetic slurry magnetic separator is widely used in

battery materials, ceramics, glass, chemical industry, electronics, food, medicine and other industries for iron impurities, magnetic substance removal and separation from slurry or glaze.